Solve connection errors on hard drives, optical drives and other devices that use flat ribbon cables to communicate. Repair a flat ribbon cable and improve performance by eliminating the number of retries that the system performs every time a data error occurs. Create a custom ribbon cable for immediate use with a few simple tools and inexpensive parts that can be kept on hand for use at times when buying a ribbon cable is inconvenient or the particular cable is no longer available.

Step 1

Cut the ribbon cable about 1/2-inch from the end that needs repair, making sure that the cut is clean and perpendicular to the cable.

Video of the Day

Step 2

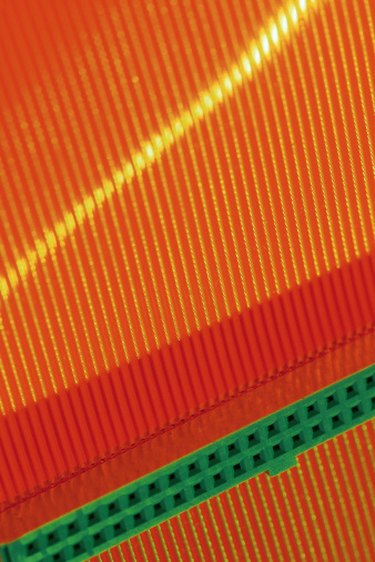

Align the connector with the cable so that the conductor marked with a colored strip on the ribbon cable is attached to pin 1 on the connector.

Step 3

Crimp the connector onto the cable firmly and with even pressure. Inspect the connection for proper alignment and seating.

Step 4

Replace badly twisted or worn ribbon cable with new cable and crimp new ends where needed.

Video of the Day